Many of Australia’s critical industries operate in harsh outback conditions. Mining, power generation, agriculture and transportation all require long-distance travel, often on unsealed roads, corrugation or off-road trails.

These environments are tough enough on their own, but they pose a serious challenge for light fleet vehicles. Off-road driving places significant strain on suspension, shock absorbers and springs, which can lead to premature failure. To avoid this, many light fleet operators choose to invest in 4WD suspension upgrades. These upgrades provide serious long-term cost savings, as well as a host of other benefits for your company, operators and fleet vehicles.

What 4WD Suspension Upgrades are Available?

Many of Australia’s fleet operators make use of world-class vehicles like the Toyota LandCruiser. These 4WDs are built tough, and they offer incredible performance straight from the factory. However, Australia’s conditions are harsh, and fleet vehicles are pushed to their limits.

In order to improve safety, performance and vehicle longevity, fleet operators invest in upgrades like:

- Heavy duty shock absorbers and springs

- Heavy duty bushes

- Suspension lift kits

- GVM upgrades

- Towing upgrades

Light fleet suspension is typically much heavier duty than factory alternatives. This is critical in environments such as mining, power generation and road transport where suspension components are expected to withstand hard use, all day, every day.

Why Invest in Light Fleet Suspension Upgrades

1. Handle Australia’s Toughest Terrain

There’s nothing more dangerous than getting stuck in the Australian outback. When help is hours or days away, it’s important to provide light fleet vehicles that can navigate the unforgiving conditions. From mine sites in outback Queensland to the sandy beaches of Western Australia, 4WD suspension upgrades are the best way to ensure your vehicles are always moving.

4WD suspension upgrades are commonly seen on light fleets operating in industries such as:

- Mining

- Refinement

- Power generation

- Transportation

- Agriculture

- Materials handling

- Construction

- Manufacturing

2. Upgrade GVM and Towing Limits

Carrying tools, equipment, operators and materials can quickly overload your vehicles, especially if you need to tow a load as well. Overloaded vehicles are inefficient and incredibly dangerous, but it’s possible to upgrade the suspension to handle the additional load.

Highly quality GVM upgrades will:

- Increase carrying capacity

- Improve ride comfort

- Improve handling characteristics

- Minimise vehicle lift

- Minimise vehicle height increase

It’s important to note that not all GVM upgrade kits are created equal. Upgrading a vehicle’s GVM can seriously affect its handling and safety characteristics. If you need to increase the GVM of your fleet vehicles, make sure you invest in products that meet Federal Department of Transport standards.

3. Protect Your Operators from Risk

Outback conditions are notoriously harsh. When your drivers travel huge distances every day, the risk of accidents and breakdowns increases exponentially. Suspension upgrades play a major role in minimising that danger to protect your company and your employees from harm.

Suspension that is specifically tuned for light fleet environments does a better job of keeping your drivers on the road. The upgraded performance makes vehicles more capable of handling off-road driving, corrugation and unsealed roads. This puts the driver in full control of the vehicle and reduces the chances of crashes, breakdowns and component failure.

4. Reduce Long-Term Operating Costs

Off-road driving is hard on your suspension, and it’s also a challenge for other vehicle components. Dusty, bouncy and rough conditions take their toll on suspension, bushes, axles, driveshafts, chassis components, wheels and tyres. When you’re running stock suspension in the Australian outback, these parts are typically overworked, which reduces their lifespan and increases maintenance requirements.

4WD suspension optimises the set up of your vehicles. This provides benefits in handling, safety and performance, but it also reduces wear and tear to vulnerable components. While upgrading the suspension on an entire fleet is a serious investment, it can dramatically decrease long-term maintenance and repair costs.

5. Increase Fleet Uptime

The reduced maintenance requirements that come with upgraded vehicle components have a knock-on effect on uptime. When vehicles spend less time in automotive workshops, they can spend more time on the road, ensuring business is always moving. Plus, the increased capability of vehicles means your operators can do more without the need for specialty equipment, further improving efficiencies on and offsite.

Increase Uptime with 4WD Suspension Upgrades from Driveline!

Keeping your light fleet moving can be a battle. When you’re up against the heat and dust of Australia’s outback, 4WD suspension upgrades can make all the difference to vehicle performance. If you’re ready to unlock the true potential of your equipment, Driveline can tailor a light fleet suspension solution to suit.

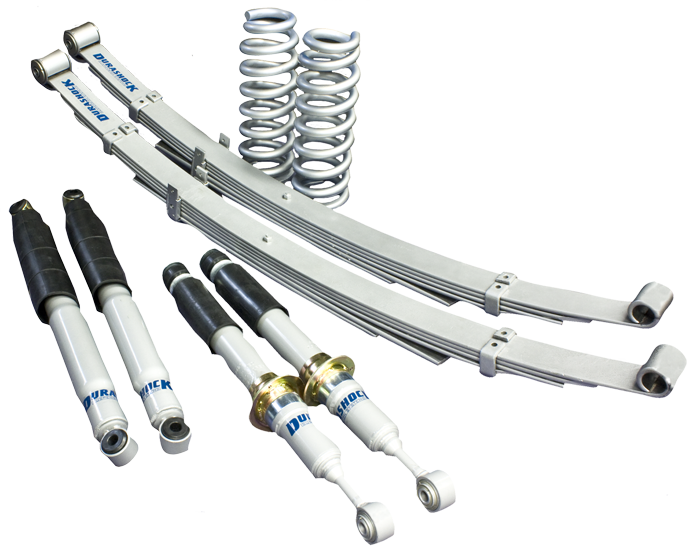

Driveline is Australia’s leading power transmission specialist. We provide suspension replacement, repairs and rebuild services for all driveline components. Our experience with mining, commercial and industrial vehicles led us to develop our own 4WD suspension system – Durashock. Durashock components are the result of continuous design and development over more than three decades. With tough construction and a twin tube gas strut design, Durashock 4WD upgrades can maximise uptime and protect your operators, regardless of the setting.

Contact us to find out about our 4WD suspension upgrade solutions, or book your light fleet vehicles into a Driveline service centre today!