Custom driveshafts are the beating heart of Australia. They power all sorts of vehicles and equipment, allowing our mining, transport, rail and maritime industries to keep moving.

These driveshafts are built by specialists like the team at Driveline. We design, manufacture, repair and rebuild custom driveshafts for some of the country’s harshest environments.

Our custom driveshaft solutions are designed for anything, and in this article, we’re going to see how they can benefit your business.

Industries We Work With

We can design a custom driveshaft for any application. We have 40+ years of experience in designing, testing, manufacturing and repairing driveshafts across our range of Markets. That allows us to design the right equipment for:

Mining

Mine sites use hundreds of varieties of vehicles, machinery and equipment. Each of these is powered by heavy-duty driveshafts.

The harsh nature of mining means that off-the-shelf driveshafts have limited use. They’re not built for abrasive, high-heat conditions, and their working lifespan is often just a few weeks.

Custom driveshafts offer greater lifespans and better repairability, which is crucial for uptime on mine sites.

Driveline designs custom driveshaft solutions for all types of mining vehicles, off-road transport, processing machinery and other equipment. We design heavy-duty solutions that can withstand any conditions, offering greater reliability and reduced costs for our mining clients.

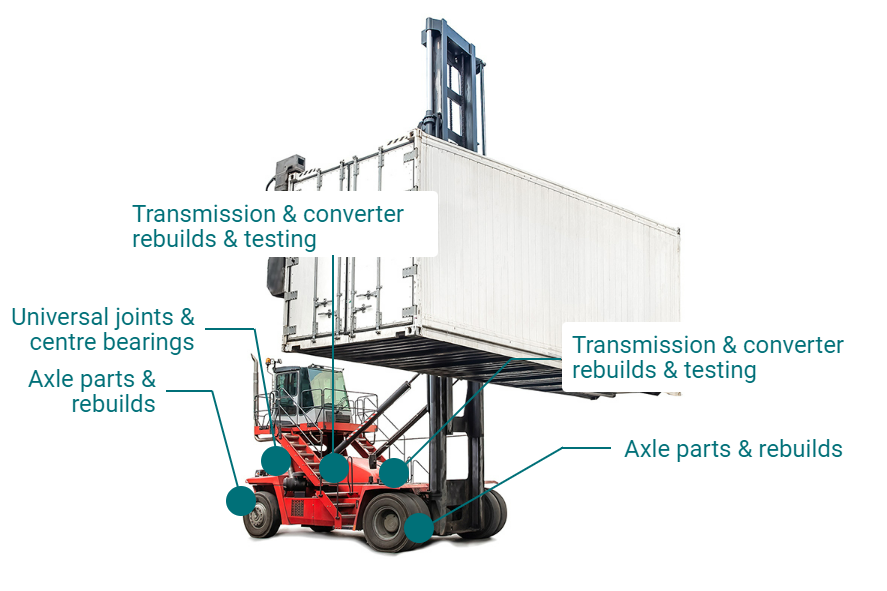

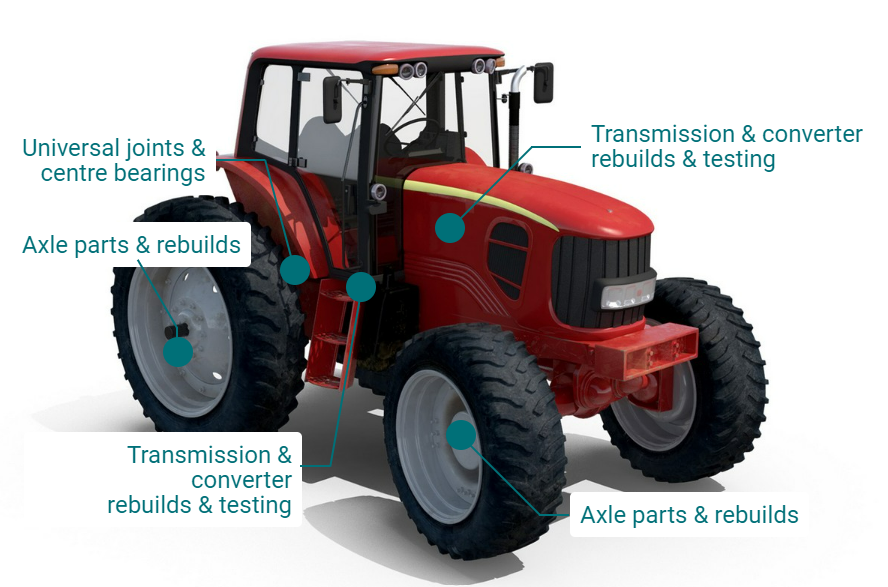

Agriculture and Material Handling

We support Australia’s supply chain from start to finish. That means our custom driveshafts are suitable for agricultural and materials handling equipment of all types.

Some of our solutions can currently be found in tractors and combines, cranes, stackers, container handlers and much more. These environments are dusty and demanding, which can be a problem for off-the-shelf components. When you work with us, we can design a custom shaft that’s ready to withstand any type of work you can imagine.

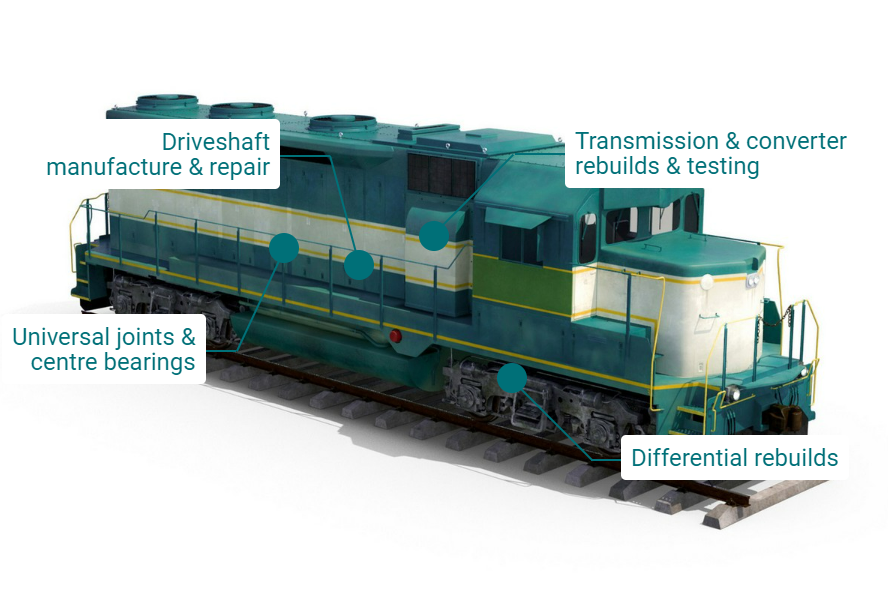

Rail and Maritime

Locomotives and marine vessels need hard-wearing driveshafts that are designed for purpose. Our custom shafts feature heavy-duty seals, tough finishes and quality components that can withstand hard use across rail and marine environments.

Industrial

Industrial machinery is often purpose-built for specific tasks. This machinery requires driveshafts that deliver maximum power, uptime and reliability, and may be no off-the-shelf solution.

Custom driveshafts are powering industrial and manufacturing equipment across Australia. We’ve previously designed shafts for manufacturing in the steel, paper and sugar industries, but our solutions are suitable for anything.

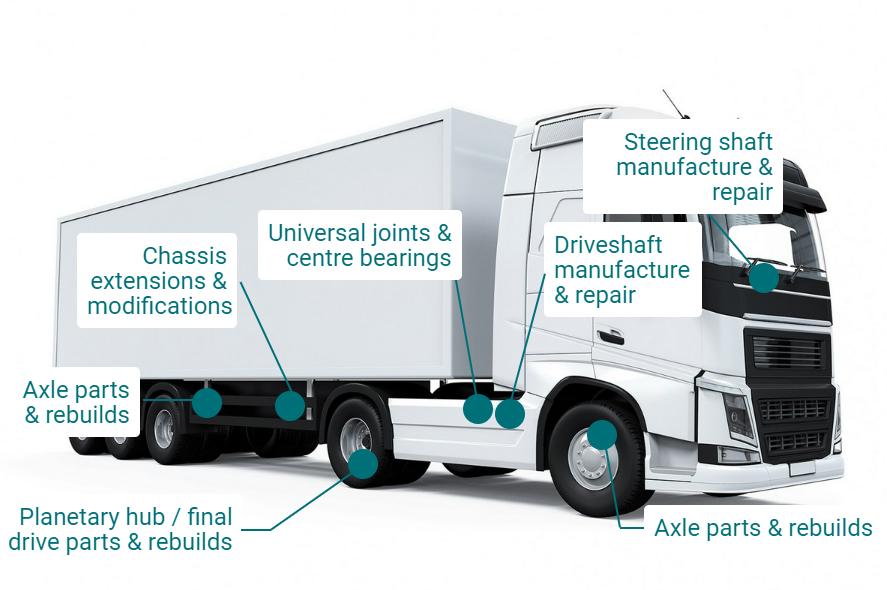

On- and Off-Road Transport

Off and On-Road transport and trucking vehicles demand heavy-duty driveline components. Custom driveshafts can be designed to withstand anything from long-distance trucking to hauling coal on an abrasive mine site.

Driveline fabricates custom driveshafts for all types of on- and off-road transport vehicles. Our solutions can be found on everything from giant dump trucks to 4×4 trucks that visit Australia’s most remote and dangerous locations.

When you need to move people, equipment or cargo and ensure it reaches its destination, our custom driveshafts will go the distance.

Performance Vehicles

Performance vehicles can lay down thousands of newtons of torque. That’s a challenge for any off-the-shelf driveshaft.

Custom driveshafts can be built tough enough to withstand any racing environment. Whether it’s high-powered dragsters or competition 4WDs that spend all their time crashing into obstacles, a custom driveshaft is the best way to put the power down.

We have the equipment and experience to build a driveshaft for any make and model of the vehicle (including custom vehicles). We’ll work with you to specify a solution that uses OEM or custom-manufactured components.

How Custom Driveshafts Can Benefit You

Extended Lifespan

OEM driveshafts typically have short lifespans in harsh environments like mining, maritime and agriculture. They may only last a few weeks before they need to be replaced. That’s a major cost and it requires frequent downtime for equipment replacement.

Driveline designs custom driveshaft solutions that are specific to your industry. We discuss the type of environment you’re working in and the application to specify a solution with the longest lifespan possible. That reduces costs and downtime, and it means you don’t need to carry a vast stock of spare parts.

Reduced Maintenance

The heavy-duty components we use to assemble custom driveshafts require less maintenance than off-the-shelf assemblies.

We choose OEM-quality components that are compatible with your use case. Depending on the workload, that means our custom driveshafts are more resistant to abrasion, corrosion, heat and cold, and knocks that could affect concentricity.

Reducing maintenance requirements can be a significant boost to productivity and allow you to avoid unplanned downtime due to equipment failure.

Suitable for Harsh Conditions

We build our custom driveshafts for the world’s harshest conditions. Whether you’re racing with thousands of horsepower, mining underground or operating maritime equipment, we can design a driveshaft that’s up to the challenge.

Designing a custom driveshaft allows us to choose components that can withstand your particular challenge. If you need something for corrosive environments, abrasive mine sites or high-torque racing, our custom driveshafts will go the distance.

Improved Repairability

Repairability is a major concern when you’re using custom equipment. Driveshafts are machined and balanced to extremely tight tolerances. When the shaft is damaged or worn down through normal use, it dramatically affects the performance of your equipment.

Custom driveshafts are designed to be repaired. They’re built from tough components that can be rebuilt or repaired by a specialist. That means you avoid the cost of replacing driveshafts with minor defects, reduces downtime and makes it easier to maintain equipment.

Built With OEM Components

Most of our driveshafts are assembled from OEM shafts, bearings and joints. That makes maintenance and repairs easier, and it means you have access to OEM-quality equipment.

When we build a custom driveshaft, we typically look for ways to use off-the-shelf components. This reduces the cost of custom equipment and gives us access to world-class brands like NSK, Koyo and Nachi.

Driveline is Australia’s Custom Driveshaft Specialist!

Driveline Services Australia has been in business for over 40 years. We have vast experience in the design, manufacture, testing, repair, maintenance and replacement of driveshaft solutions.

Our custom driveshafts are hard at work in some of Australia’s harshest conditions. With clients in mining, manufacturing, agriculture, power generation and more, we’re doing our part to keep the country moving.

Each of our custom driveshaft solutions is tailored to your needs. If you need a custom shaft for vehicles or equipment, talk to our team, and we can design something that’s perfect for your application.

Contact us for a quote, or visit our Workshop Services page to find out more.